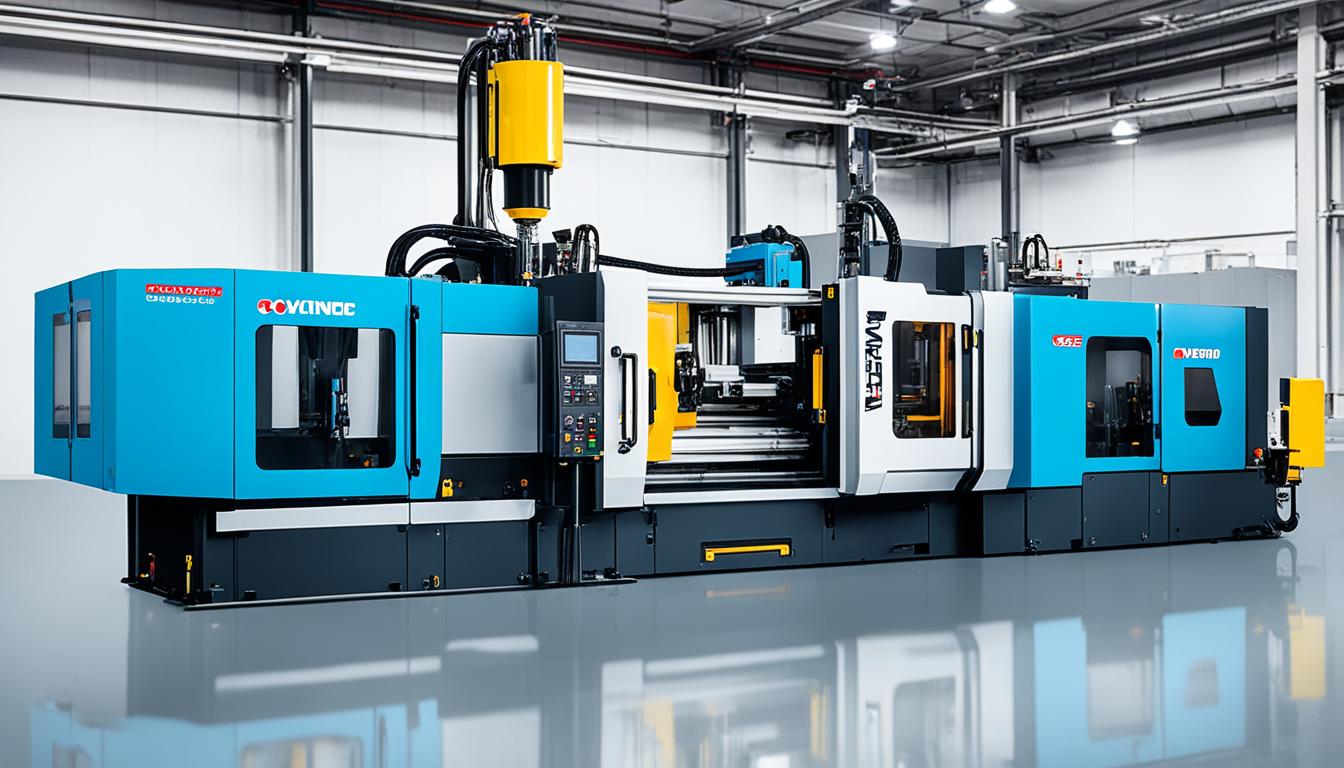

When looking at plastic THY Precision injection molding machine types, you have three main choices: hydraulic, electric, and hybrid. Each type has its own pros and cons. It’s important to know these differences to pick the right one for your project. The choice of Injection Molding Machine Types greatly affects your production’s quality, speed, and cost.

But what makes these injection molding machine types different? And which one should you choose? As a design engineer, you might ask: What are the main differences between hydraulic, electric, and hybrid Injection Molding Machine Types, and how do they affect my production?

Key Takeaways

- Hydraulic, electric, and hybrid are the top injection molding machine types used in making plastics.

- Each injection molding machine type has its own strengths and weaknesses, like precision, energy use, and cost.

- It’s key to understand these differences to pick the best injection molding machine for your project needs.

- The injection molding machine you pick can greatly change your production’s quality, speed, and cost.

- Looking into the good and bad of hydraulic, electric, and hybrid injection molding machine types helps you make a smart choice for your plastic making work.

Understanding Injection Molding Machine Types

In the world of injection molding, choosing the right machine type is crucial. Injection molding machine types vary, but hydraulic machines are a top pick, especially in the automotive sector.

Hydraulic Injection Molding Machines

Hydraulic injection molding machines started in the late 1930s and were a big deal back then. They use hydraulic cylinders to press the mold halves together tightly. Then, plastic pellets melt and the liquid plastic is pushed into the mold.

These machines are great for making big, heavy parts like car bumpers. They can handle clamp forces up to 8,000 tons and make parts over 50 pounds.

| Feature | Hydraulic Injection Molding Machines |

|---|---|

| Clamp Force | Up to 8,000 tons |

| Part Weight | More than 50 pounds |

| Applications | Automotive industry (e.g., bumpers) |

Even though electric machines came along in the 1980s, hydraulic injection molding machines are still important. They’re great for making big, heavy parts.

Electric Injection Molding Machine Types: A Precise and Energy-Efficient Alternative

Traditional hydraulic injection molding machine types used to be the top choice. But now, electric injection molding machines are changing the game with their precision and efficiency. They started in 1984 in Japan and quickly became popular, now making up over half of all IMM machines sold in the U.S.

Electric injection molding machines use high-speed servo motors for power, not hydraulics. This means they work faster and more consistently. They’re perfect for making small to medium-sized parts, like medical items such as Petri dishes and syringes.

Advantages of Electric Injection Molding Machines

- Energy-efficient operation, reducing power consumption and costs

- Precise, repeatable, and consistent injection process for improved part quality

- Faster cycle times and increased productivity

- Quieter operation and reduced maintenance requirements

- Ideal for cleanroom environments and small- to medium-sized parts

Electric injection molding machine types are becoming a top choice for many manufacturers. They’re getting more energy-efficient, precise, and versatile. The future of injection molding machine types looks bright.

Hybrid Injection Molding Machine Types: Combining the Best of Both Worlds

The hybrid injection molding machine is changing the game, blending hydraulic and electric machine strengths. THY Precision leads in this new tech, offering solutions for the industry’s varied needs.

Benefits of Hybrid Injection Molding Machines

THY Precision’s hybrid machines bring power, precision, and energy efficiency together. They use hydraulic power for strength and electric motors for precision and quietness. This mix lets them make parts of any thickness with top-notch quality.

These machines are also energy savers. The mix of hydraulic and electric parts means they last longer and use less energy. This cuts down on costs and speeds up the return on investment for companies.

| Feature | Benefit |

|---|---|

| Superior Clamping Force | Ability to handle a wide range of part sizes and complexities |

| Precise and Repeatable Performance | Ensures consistent product quality and minimizes waste |

| Reduced Energy Consumption | Lower operating costs and faster return on investment |

| Quiet Operation | Improved work environment for operators |

THY Precision’s hybrid machines combine hydraulic and electric strengths. This gives businesses in manufacturing top performance and cost savings.

Conclusion

Choosing the right injection molding machine depends on your project’s needs. Each type – hydraulic, electric, and hybrid – has its own pros and cons. Hydraulic machines are powerful but less precise. Electric ones are precise but use less energy. Hybrid machines mix the best of both.

The right machine type depends on your parts’ complexity, how much you produce, energy use, and costs. THY Precision suggests looking at your needs and exploring different machines to find the best fit for your business. This way, you can make a smart choice that ensures quality parts and saves costs.

Choosing any injection molding machine type, THY Precision is ready to help you succeed. We support both experienced manufacturers and newcomers in the industry. Contact us to see how we can help you improve your injection molding operations.